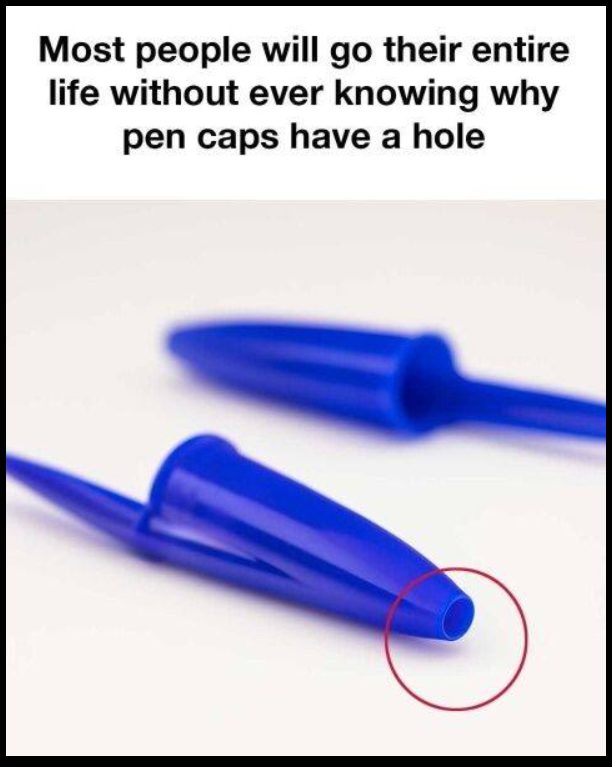

Most people might not realize it, but the little hole you often see at the top of a pen cap isn’t just a random design choice or an accidental feature—it’s actually the result of clever and thoughtful engineering. Pen caps are designed not just to protect the tip of the pen from drying out or getting damaged, but they also incorporate tiny holes that serve several important purposes.

One of the most critical reasons for this design is safety. Believe it or not, the hole in the cap can actually save lives. If someone, particularly a child, accidentally swallows a pen cap and it gets lodged in their throat, the hole allows for a small amount of air to pass through. This airflow can help prevent suffocation long enough for emergency responders to assist, making it a vital, life-saving feature that most people overlook. Pen manufacturers began introducing holes in caps after safety regulations were developed to reduce choking hazards, and now it’s become a standard feature across many brands.

Beyond the obvious safety concerns, the hole in the pen cap also serves a functional purpose related to the pen’s performance. When you use a pen, especially in different environments where air pressure might vary, the hole helps equalize the pressure inside the pen. This small but crucial detail prevents ink from leaking out when the pen experiences changes in altitude or temperature, and it ensures that the ink flows smoothly when you’re writing. Without the hole, you might experience frustrating ink blobs or inconsistent writing, especially when traveling by airplane or moving between high and low elevations. But that’s not all—the hole also plays a significant role in manufacturing. Producing millions of pen caps requires enormous amounts of material, and even a tiny reduction in the amount of plastic used for each cap can add up to huge savings. By incorporating a hole in the cap, manufacturers use slightly less plastic and can also speed up the production process.

The mold used to create the cap cools and sets faster thanks to the hole, making the entire operation more efficient and cost-effective. Over time, these small savings translate into lower production costs, which benefits both the companies making the pens and the consumers buying them.

Furthermore, some brands have even embraced the hole as part of their distinctive design language. In a crowded market where hundreds of pen styles compete for attention, a unique cap design can make a pen instantly recognizable. For example, companies like BIC have turned their cap designs, holes included, into iconic features that people associate with quality and reliability. In this way, what started as a practical safety and functional feature has also become a branding tool that helps companies stand out. So the next time you absentmindedly chew on a pen cap or twirl it in your fingers during a meeting, take a moment to appreciate the thoughtfulness behind that tiny hole. It’s not just a random feature or a manufacturing shortcut—it’s an example of how careful design can blend safety, functionality, cost-efficiency, and style into something as ordinary and overlooked as a pen cap. Every detail, even something as small as a tiny hole, has a purpose that improves the overall user experience while keeping safety at the forefront. It’s a perfect reminder that good design often hides in plain sight, quietly making our everyday lives easier, safer, and more enjoyable without demanding our attention. The next time you pick up a pen, you’ll know there’s much more going on than meets the eye, and you’ll probably never look at a simple pen cap the same way again. It’s just one more example of how even the smallest details are the result of smart engineering and thoughtful design choices, shaping the tools we use every single day without us even realizing it